GKN and Porsche Develop AM Transmission Part Using New Metal Powder

Using a combination of metal powder-bed fusion and metal powder 20MnCr5, GKN Powder Metallurgy and Porsche 3D-printed an intricate differential housing with gear ring unit on a front traverse transmission.

Today’s automotive manufacturers are faced with the ever-increasing demand of improving vehicle efficiency. Manufacturers have tackled the problem from all angles: reducing weight, creating more efficient internal combustion engines, improving powertrains, and reducing noise. But to achieve a more efficient vehicle, the automotive market has started using metal additive manufacturing (AM)

Metal AM enables the development of innovative solutions and shortens time-to-market duration. AM is used for prototyping parts and to mass manufacture parts that require a unique shape, typically impossible to achieve via traditional machining. For automotive, the development of more efficient powertrains, combined with AM design freedom, enables the creation of functional-integrated and weight-reduced AM steel grades that still withstand high wear and loads.

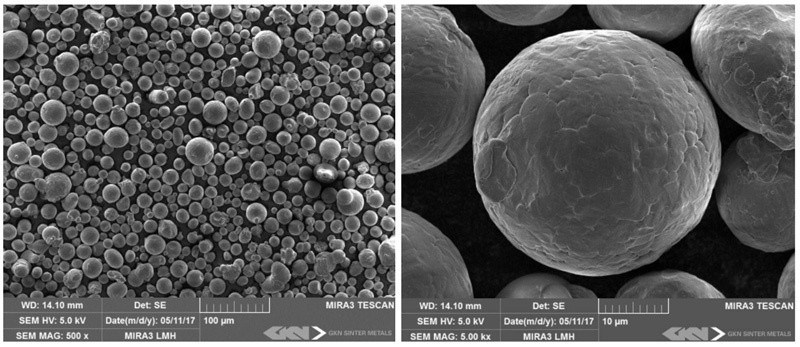

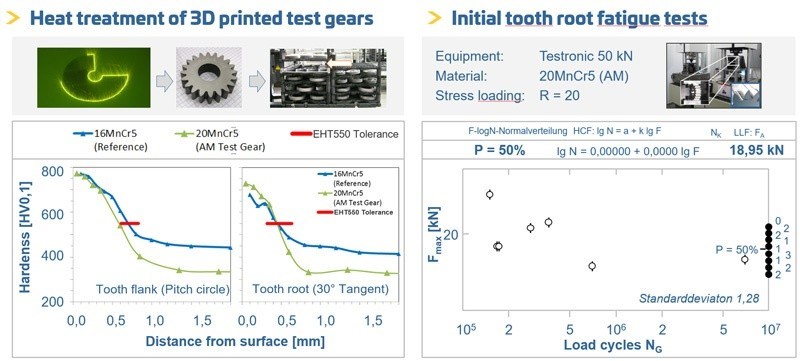

GKN Powder Metallurgy has developed a powder material designed to fit the requirements of the automotive industry: 20MnCr5. This steel grade powder is said to offer ductility without compromising strength, wear resistance through case hardening, high fatigue strength and toughness that doesn’t detract from machinability. This material can form a medium-strength steel grade able to be case-hardened and which has high wear resistance, mechanical strength and performance-to-cost ratio, the company says. Furthermore, initial test results indicate that 20MnCr5 can meet current 16MnCr5 medium steel quality levels.

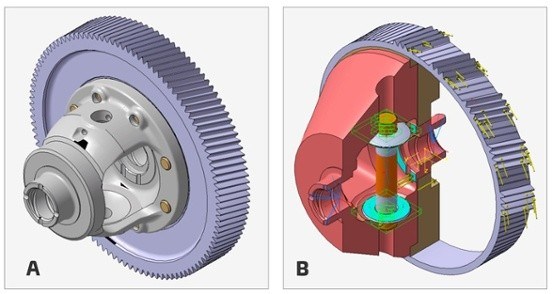

To validate these results, GKN and Porsche used 20MnCr5 to 3D print a conventional front transverse transmission. They chose to design the transmission part with the largest weight reduction potential: the differential housing with ring gear unit. Ultimately, they created a more efficient transmission part that could not have been produced without AM.

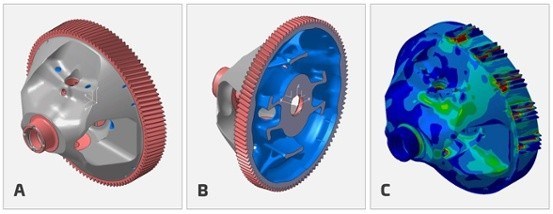

Using CAD and topology structural optimization software, GKN and Prosche designed a new shape for the differential housing with ring gear unit. They first defined the maximum available space within the transmission and subtracted the inner contours needed by any function (bevel gears, side shafts, bearings, etc.) from the body of the part (see Figure 4).

Based on the specifications and requirements of the transmission, all loads (bearing and gear) were applied to the package block. The CAD optimization tool delivered a structure capable of taking all required loads. The resulting structure (Figure 5) is not producible with conventional tools, but creating the product close to the calculated structure is possible with AM. For example, the inner shape of the differential housing part is supported by a system of organic beams and structures that are necessary for its structural integrity. While these shapes cannot be machined with traditional methods, AM enabled the part to be printed from scratch. The AM process does require that the part be designed with special features such as holes to eject the unused metal powder or openings on the outer diameter to drain collected oil, but these features can be designed into the model from the beginning.

The final finite element analysis showed a very homogeneous stress level. This enabled a reduction in wall thickness, a characteristic not previously possible. Based on the original load requirements, the calculation achieved a 13 percent weight reduction, a 43 percent reduction of tooth stiffness variations in radial direction, a 69 percent reduction of tooth stiffness variations in tangential direction and an 8 percent reduction of inertia.

The use of AM with special metals like 20MnCr5 introduces a future of metal additive production that yields parts that are weight efficient and structurally strong.

Adapted from an article that originally appeared on GKN’s blog.

Related Content

500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read MoreUMaine’s FoF 1.0 Large-Scale 3D Printer Shatters Former Guinness World Record for Additive Manufacturing

The large-scale thermoplastic polymer printer offers new opportunities for eco-friendly and cost-effective manufacturing for numerous industries, including national security, affordable housing, bridge construction, ocean and wind energy technologies, and maritime vessel fabrication.

Read MoreShape Lab Develops MyCera to Reinforce 3D Printed Clay Structures

Mycelium is an intelligently oriented fiber reinforcement that can increase the structural performance of 3D printed unfired clay elements and enable bio-welding of fired elements.

Read MoreUSAF, GE Additive 3D Print Out-of-Production Metal Parts

The upcoming final phase of the Pacer Edge program is to establish the USAF’s own metal additive production infrastructure initially at Tinker Air Force Base in Oklahoma.

Read MoreRead Next

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More

.png;maxWidth=300;quality=90)