IMTS 2024 Floor Plan Reflects Manufacturing Strength and Growth

IMTS 2024 is now organized by manufacturing sectors to help visitors compare capabilities, prices and services from the world’s elite suppliers all in one location.

NFL coaching legend Vince Lombardi once said, “Perfection is not attainable, but if we chase perfection, we can catch excellence.” With the unveiling of the IMTS 2024 floor plan, I can confidently state that IMTS and the manufacturing industry are catching excellence in many ways.

First, the exhibition space rebooking rate is as high as it has ever been, outpacing even IMTS 2018 or the dot-com boom years. Prominent exhibitors are expanding their footprint, and companies that had paused their marketing plans have recommitted to IMTS 2024. The show is on pace to exceed the 2022 show, which had 1.2 million square feet of exhibit space and more than 1,800 exhibiting companies.

The focus on IMTS 2024 remains intense because we need a strong manufacturing industry. Here are four factors to consider:

- The monthly average of capacity utilization rates for durable goods manufacturing has remained above 75% for the last year.

- Manufacturing is also the beneficiary of the $1.2 trillion Infrastructure Investment and Jobs Act of 2021, and the $280 billion CHIPS and Science Act of August 2022.

- According to the latest U.S. Manufacturing Technology Orders Report published by AMT, new orders of manufacturing technology totaled $543.2 million in March 2023, one of the largest March totals since 2008.

- According to the Reshoring Initiative, there is a desire for greater self-sufficiency that will result in the reshoring of an estimated 400,000-plus jobs in 2023.

New Manufacturing Sectors

To meet the needs of a robust manufacturing industry, IMTS 2024 will have even more exhibits that feature robotics, advanced motion systems, vision and imaging, data analytics, systems integration, software, artificial intelligence and connected technologies.

Going back to the quote from Vince Lombardi, I believe catching excellence demands change and growth. In that spirit, the IMTS 2024 floor plan has a fresh look. So that visitors can compare capabilities, prices and services, IMTS 2024 is now organized by manufacturing sectors. The sector approach helps visitors capture everything they need to know from the world’s elite suppliers in one location.

A great place to start exploring the sectors at IMTS 2024 is in the new Automation Sector, accelerated by SPS – Smart Production Solutions, which will occupy the North Building. Locating the Automation Sector in the North Building frees up space in the East Building for the fast-growing Quality Assurance Sector and the Software Sector. The Fabricating and Laser Sector will also occupy

the East Building.

The Smartforce Student Summit will relocate to the second level of the East Building. This move reduces the distance between the student bus drop-off/pickup location, as well as the distance to the IMTS show floor, which improves logistics for schools and summit visitors.

As more businesses integrate additive manufacturing (AM) into their operations, they will want to plan more time in the Additive Manufacturing Sector, accelerated by Formnext. AM, automation and digital manufacturing are inherently intertwined, which will be reflected in their growing prominence at IMTS 2024.

Technology Addresses Demographic Challenges

As OEMs and job shops consider their plans for IMTS 2024, they also need to consider the reality of manufacturing demographics that demand they produce more products with their existing workforce.

Labor markets remain incredibly tight despite concerns of a slowing economy. Industrial robot orders continue to increase. According to the World Economic Forum’s “Future of Work Survey 2020” report, 78% of companies surveyed in the U.S. said they are “likely” or “very likely” to deploy robots — by 2025. According to the U.S. Chamber of Commerce, there are 9.9 million job openings in the United States, but only 5.8 million unemployed workers. Baby boomers are retiring; there are too few workers in Generation X; and manufacturing is not attracting and retaining enough younger workers.

The solution for too few workers and strong demand is more technology and finding ways to work smarter — a situation IMTS was built to address. Visitors and exhibitors can count on IMTS 2024 being the industry epicenter for discovering ideas, exploring innovations, and reaffirming the value of personal connections. Explore IMTS 2024 at imts.com.

Related Content

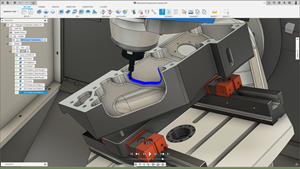

Autodesk Fusion 360 Software Enables Generative Additive Manufacturing

IMTS 2022: This cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform for product design and manufacturing is said to help users design, engineer and manufacture products to ensure aesthetics, form, fit and function.

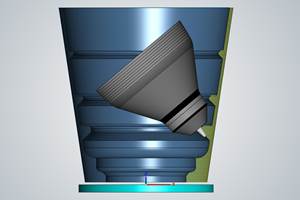

Read MoreHyperMill CAM Software for Hybrid Manufacturing

IMTS 2022: The hyperMill CAM software features an additive manufacturing capability option, which is said to provide efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

Read MoreRecapping the Additive Manufacturing Conference 2022: AM Interacts With Conventional Processes: AM Radio #26B

On the AM Radio podcast, impressions of this year’s Additive Manufacturing Conference at IMTS. A notable element this year was attention to AM’s impact on processes such as casting and machining

Read MoreFast Wire EDM Machines Remove 3D-Printed Metal Parts From Large Build Plates

IMTS 2022: EDM Network’s mid-sized, four-axis Fast Wire EDM machine is said to provide three to four times faster cutting power.

Read MoreRead Next

GE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read More

.png;maxWidth=300;quality=90)