Porsche Advances Electrification with Generative Design

The sports car manufacturer achieves weight savings and assembly consolidation using additive manufacturing instead of casting for an electric drive housing.

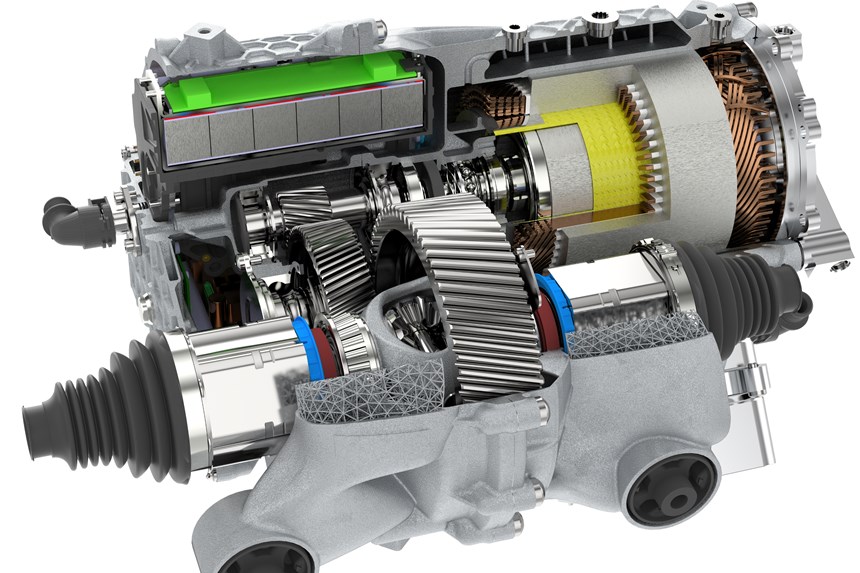

Like all automotive OEMs Porsche is working to electrify its lineup, which can mean providing electric motors to supplement internal combustion engines. In this configuration, the 800-volt permanent magnet motor has a gearbox that then coordinates with the engine, with the package being located on the front axle of the car.

Two aspects of this: (1) there are demanding packaging considerations because of the fundamental limitations of the parameters of the chassis; (2) the motor drive housing must be light.

Generative & Additive

So the company is using two technologies that allow them to realize an electric drive housing that they think could be deployed in a limited-edition super sports car: additive manufacturing and generative design.

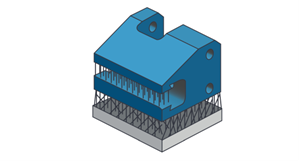

The printed housing with support structures.

Falk Heilfort, Project Manager in the Powertrain Advance Development department, explains, “Our goal was to develop an electric drive with the potential for additive manufacturing, at the same time integrating as many functions and parts as possible in the drive housing, saving weight and optimizing the structure.”Engineers working on the electric drive took into account elements of the system including the bearings, heat exchangers and oil supply and modeled the loads and interfaces. Load paths were determined and lattice structures were defined, with areas that are under more stress enhanced and those under less load reduced in overall size.

Engineers working on the electric drive took into account elements of the system including the bearings, heat exchangers and oil supply and modeled the loads and interfaces. Load paths were determined and lattice structures were defined, with areas that are under more stress enhanced and those under less load reduced in overall size.

According to Sebastian Wachter, Specialist in Design Methodology and Topology Optimization in the Porsche Powertrain Advance Development department, “We were able to expand and improve our software solutions and methods for creating such parts and are now able to virtually implement them in a very short space of time.”

The designers and engineers used two software programs in the development of the housing: Altair Inspire for early work, then Dassault CATIA V5 to complete it.

The structure as designed required the use of additive manufacturing as the configuration didn’t lend itself to conventional casting.

Selective laser melting being performed at Porsche.

Process & Material

The build was performed on an NXG XII 600 machine from SLM Solutions. The machine has 12 overlapping 1-kW lasers. It has a build envelope of 600 x 600 x 600 mm.

The material used for the housing is an aluminum alloy, AlSi10Mg.

Porsche engineers aren’t strangers to 3D printing. “Thanks to the new, lighter pistons, we can increase the engine speed, lower the temperature load on the pistons and optimize combustion. This makes it possible to get up to 29.5 hp more power from the 690 hp biturbo engine, while at the same time improving efficiency,” said Frank Ickinger of the advance drive development department at Porsche.

The printed part provided plenty of benefits. For example, although there is a continuous wall thickness of 1.5 mm, the use of the lattices in the design resulted in a stiffness increase between the gearbox and the motor of 100%.

Through the integration of parts and topology optimization the weight of the housing was reduced by some 40%. The parts integration also meant less assembly to build the housing is necessary: about 40 steps or 20 minutes are removed.

Although those numbers are impressive, we were told by Porsche, “With the machine technology currently available, printing of the first housing prototype took 19 days and had to take place in two build processes due to the component size.”

That said, the company kept at it.

Porsche 911 GT2 RS: Why wouldn’t you use pistons produced with additive—lighter weight means faster performance.

“With the latest machine generations that we used for a second prototype, it was possible to reduce this time by 90% to now about 21 hours, and the entire housing could be manufactured in just one build process.”

It is worth noting that the volumes at Porsche are . . . comparatively limited. In 2020 the company delivered a total 272,162 vehicles on a global basis. Of that number, 34,328 were the iconic 911.

So even if it takes hours to produce things like housings, it is certainly in keeping with the company’s production cadence.

Related Content

Video: 3D Printing Paired with Plastics Joining

Conventional 3D printing wisdom is to combine as many components as possible into one 3D printed piece. Plastics joining technology expert Extol illustrates the benefits that come from printing in many pieces instead.

Read MoreCreating Designs That 3D Printing Experts Love

3D printing can create virtually any shape imaginable, but that doesn’t mean it will be easy to print. How to design parts that are printable as well as functional.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreRead Next

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)