America Makes Announces Winners for IMPACT Project Call

The project call focuses on additive manufacturing research related to casting and forging, metal powder sourcing and robotic AM process planning for continuous fiber-reinforced composite structures.

The National Center for Defense Manufacturing and Machining (NCDMM) and America Makes have selected the winners of the “Improvements in Manufacturing Productivity via Additive Capabilities and Techno-Economic Analysis (IMPACT)” directed project call. Funding for this project call is provided by the Office of the Under Secretary of Defense, Research and Engineering Manufacturing Technology Office (OSD(R&E)) and the Air Force Research Laboratory (AFRL), worth a total of $11.7 million.

The objective of the IMPACT project call is to demonstrate productivity and yield benefits for casting and forging manufacturing via additive manufacturing (AM) technologies, execute techno-economic analysis for metal powder AM, and to bridge component sourcing gaps with AM parts for casting and forging applications. Additionally, the project call was seeking innovative solutions in robotic AM process planning for continuous fiber-reinforced composite structures.

AM is of significant interest to the U.S. manufacturing base as the technology enables shorter lead times, mass customization, energy reduction, complex shapes and production of parts on demand, providing benefits to both new acquisitions and legacy systems.

“This project call addresses the needs of a broad cross section of our nation’s supply chain, including the casting and forging industry,” says Brandon Ribic, Ph.D., America Makes Technology Director. “The U.S. government considers metal casting and forgings to be one of the most critical supply chain items to our national defense and economic health. Thus, we see the need for casting and forging operations to seek advanced manufacturing capabilities that can upgrade production capacity, improve throughput, reduce cost and take risks out of the supply chain equation. The awardees of this project call will work to shed light on the critical need for long-term strategic investments in AM to strengthen the U.S. supply chain.”

Additionally, the techno-economic analysis study on metal powder AM seeks to prioritize investment areas to improve the business case for one of the most mature AM processes. The research in robotic planning strategies for continuous fiber-reinforced printing aims at reducing the producibility barriers of autonomous unmanned aerial vehicles. “Applying the full 3-dimensional power of advanced manufacturing technologies, such as industrial robotic arms to use for AM applications can unlock many unseen potentials,” says John Martin, America Makes additive manufacturing research director.

Below is the list of award winners and related topics/projects:

Topic 1: Develop/disseminate leading practices and accelerate the adoption of 3D printed molds/cores for sand castings

- Project 1: Implementing Best Practices and Technology Improvements for 3D Printed Molds/Cores for Sand Castings

- Team Lead: Honeywell International

- Project Team: American Foundry Society; Chicago Magnesium Casting Co.; ExOne; Hoosier Pattern; Ohio Aluminum Industries

Topic 2: Mature AM ceramic technology and promote adoption for rapid, low-volume production of investment castings for defense applications

- Project 1: AM Ceramic Shell Technology for Investment Casting

- Team Lead: Investment Casting Institute

- Project Team: Alfred University – Center for Advanced Ceramic Technology; Barron Industries; Bescast; Concurrent Resources; Intrepid Automation; Kovatch Castings; Lithoz America; Metaltek International – Wisconsin Investcast Division; Missouri University of Science and Technology; O’Fallen Casting; Pennsylvania State University; Product Development & Analysis; Rangeview; SeaCast; Shell Cast; Signicast; Tethon 3D; University of Arizona; University of Texas El Paso

- Project 2: 3D CREATE – 3D Ceramic Research and Extensive Application of Tools for Engineered Molds

- Team Lead: Renaissance Services

- Project Team: Aspen Technology; Product Development & Analysis; The Ohio State University, Center for Design and Manufacturing Excellence; University of Northern Iowa Metal Casting Center

- Project 3: Maturation of Ceramic 3D Printed Shell-Based Investment Casting Foundry Capabilities of the 76th CMXG at Tinker Air Force Base

- Team Lead: DDM Systems

- Project Team: Air Force Sustainment Center 76 CMXG, Mueller Additive Manufacturing Solutions

Topic 5: Optimizing Forging Preforms Production Using Different Additive Manufacturing Routes: Process Selection, Testing and Performance Evaluation

- Project 1: Pilot the Industrialization of AM preforms to Expedite the Forging Process for Low-Volume Forged Components|

- Team Lead: Cleveland State University

- Project Team: Canton Drop Forge; FasTech; Forging Industry Association; Georgia Southern University; SIFCO Industries; and Wright State University

Topic 6: Develop and disseminate leading DED and cold spray practices to promote adoption of die repair for forging applications

- Project 1: DED Additive Manufacturing for Forging Die Repair

- Team Lead: Cleveland State University

- Project Team: Absolute Welding and Machining; Canton Drop Forge; FasTech; Forging Industry Association

Topic 8: Techno-economic analysis and manufacturing readiness assessments to address bridging component sourcing gaps with AM parts for critical casting and forging production

- Project 1: Casting and Forging Techno-Economic Framework

- Team Lead: Deloitte Consulting

- Project 2: Techno-Economic Analysis and Assessment to Bridge Sourcing Gaps between Casting and Forging to Additive Manufacturing

- Team Lead: Wichita State University – National Institute for Aviation Research

- Team Lead: Wichita State University – National Institute for Aviation Research

Topic 9: Powder AM techno-economic analysis

- Project 1: Techno-Economic Analysis of Powder Bed Fusion for the Air Force

- Team Lead: American Society for Testing and Materials (ASTM International)

- Project Team: Wohler Inc.

Topic 10: Innovations in robotic additive manufacturing process planning

- Project 1: 3D Toolpathing Software Advancements for Steered Continuous Fiber Robot Process Planning

- Team Lead: Continuous Composites

Project teams will report on their progress with these projects at the America Makes Technical Review and Exchange, and other industry events during the execution phase of the program.

Related Content

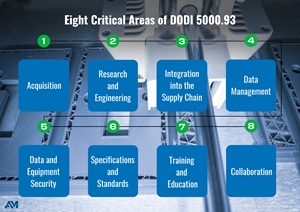

DOD Drives Transformation with New AM Policy

The U.S. Department of Defense published DODI 5000.93, a comprehensive plan for implementing additive manufacturing among military services.

Read MoreJuggerBot 3D Awarded $4 Million by Air Force to Develop Large Format Hybrid Additive System

The project focuses on advancing the ability to print a thermoset composite material that can transform the way an aircraft structure is designed, fabricated and sustained for limited-life aircraft.

Read More7 Takeaways From America Makes MMX 2023

America Makes just held its recent Members Meeting & Exchange. Here are observations related to cost and collaboration; digital manufacturing; and the sustainment and supply chain needs of the DoD.

Read MoreFrom Polymer Tooling to Metal Production Via 3D Printing

As Azoth has adopted new additive manufacturing technologies, its work has transitioned from tooling to production parts for automotive, medical and defense.

Read MoreRead Next

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More

.png;maxWidth=300;quality=90)