Catalysis Additive Tooling Licenses 3D Printed Tooling Technology in Europe

The innoMold company will spearhead the tool manufacturing operating under the name “Catalysis Additive Tooling GmbH,” beginning operations in October 2023.

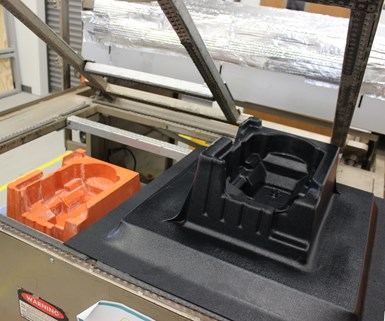

A sand 3D-printed tool (left) for vacuum forming and the part it produced. Catalysis Additive Tooling produces prototypes and short runs of parts using this vacuum-forming machine in its Advanced Manufacturing Center in Powell, Ohio. Larger volumes are manufactured by strategic partners. Photo Credit: Catalysis Additive Tooling

Catalysis Additive Tooling, the provider of 3D printed tooling solutions in North America, is licensing its 3D printed tooling technology to innoMold, a company based near Düsseldorf, Germany.

Operating under the name “Catalysis Additive Tooling GmbH,” innoMold will spearhead tool manufacturing using this technology, beginning operations in October 2023. With the incorporation of 3D printed tooling technology used in thermoforming, seat foam manufacturing, jigs and fixtures among other uses, customers worldwide can now substantially reduce tooling costs and manufacturing time, leading to faster product launches and decreased cost per unit.

“I'm thrilled to announce the licensing of our 3D printed tooling technology in Europe,” says Darrell Stafford, Catalysis Additive Tooling President/CEO. “The remarkable company culture and determination exhibited by innoMold make them an ideal partner for Catalysis as we aim to strengthen our global leadership position in 3D tooling applications.”

Catalysis Additive Tooling is building a one-stop supply chain for production quantities ranging from one to one million in which 3D-printed tooling and relationships are key.

“Adding this state-of-the-art tooling technology to our existing 3D printing solutions portfolio marks a significant milestone for innoMold,” says Jean-Christophe Figueroa, CEO of Catalysis Additive Tooling GmbH. “The innovative spirit and customer-centric approach of the Catalysis team align seamlessly with our company culture.”

Founded in 2016 by Darrell Stafford and Rick Shibko, Catalysis has benefited from its extensive 60 years of combined experience in automotive manufacturing, establishing a solid foundation for the company. Over the years, Catalysis has successfully manufactured more than 1,300 tools, serving over 110 customers.

The innoMold company is an affiliate of the innoCast Group, which was established in 2003 and managed by Dr. Thomas Bettermann, Jean-Christophe Figueroa and Ekkehard Petzold, all with extensive experience in the industry and automotive sector. Over the past two decades, the Group companies have delivered more than 50,000 parts made with in-house 3D printed tools to 250 customers across 24 countries.

- Learn more about Catalysis’s 3D printed tooling which supports prototype foam seating. Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

- Read how manufacturers can 3D print the tool to cast the mold to make the part. 3D-printed molds to manufacture parts are familiar, but what if the mold itself was made with a 3D-printed tool? Catalysis Additive Tooling proves out this concept in a mold for a fiberglass part.

Related Content

-

Video: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

-

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

-

3D Printing Supports Induction Coils — and Emergency Needs

As a participant in Michigan’s Project DIAMOnD initiative, Tucker Induction Systems received a 3D printer to use any way it saw fit, provided the capacity remains available in case of emergency. Use cases and lessons learned as part of this distributed manufacturing network.

.png;maxWidth=300;quality=90)