Hasbro Uses Formlabs 3D Printing Technology to Create Custom Action Figures

Hasbro ushers in a new era of mass customization in consumer entertainment with its Selfie Series figures using 3D printing to manufacture personalized action figures at scale.

Hasbro is creating Selfie Series figures using Formlabs’ 3D printing technology to manufacture personalized action figures at scale. Now, fans can scan their face with a smart device and have a custom-made, look-a-like action figure.

This offering is the culmination of years of Hasbro investment in Formlabs’ stereolithography (SLA) additive manufacturing (AM) technology, along with a drive to bring fans closer to the worlds they love. Hasbro says it has seen an increased demand for toy customization, but it has always been a major challenge to deliver at scale, balancing quality, speed to market and price. Now, it says it has a scalable solution.

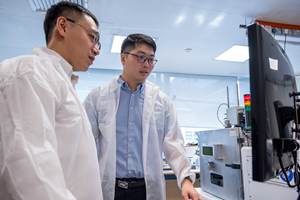

It wasn’t until recently that two technologies collided to make everything possible — easy-to-use, mobile facial scanning technology and affordable, high-quality in-house SLA 3D printing. Once Hasbro saw the opportunity to expand the use of AM outside of prototyping, it decided to invest in an agile digital factory of Formlabs 3D printers.

A Hybrid Manufacturing Approach

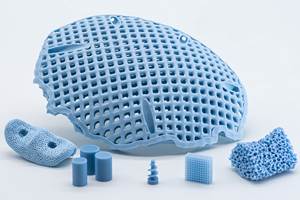

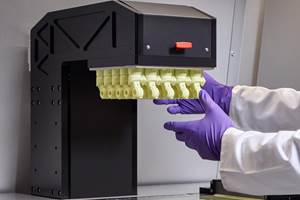

Manufacturing the customized figures is a hybrid approach. Hasbro continues to use the classic, mass-produced, injection-molded action figure body, but now it’s combined with a 3D printed head and hair to make one, complete figure. While the majority of the toy is injection molded — which enables the company to keep the costs in check — the head of the action figure, which is the most important part, can now be customized before being securely attached. By using software to pair the customers’ facial scan with their hair color choice, Hasbro was able to set up a scalable production system which matches the mass-produced bodies with the custom heads and hair pieces coming off the 3D printers.

Hasbro says it chose Formlabs’ technology because of the ability to create and print with a custom resin. With over 20-plus materials — from strong tough parts that don’t break under pressure to flexible and elastic parts that bend — Formlabs’ SLA machines offer solutions for a wide range of applications. In this case, the need for a range of hues for hair and skin colors, all of which shared the same mechanical properties, meant the need for a custom resin.

Based on its Tough 1500 material, Formlabs put its team of materials scientists at Hasbro’s disposal, working closely to deliver the required material. Best of all, this new material worked on the standard Form 3, meaning that Hasbro didn’t need any special hardware upgrades. With a resin production center in the U.S., a local supply chain for long-term production was guaranteed, meaning Hasbro could scale this material with demand.

Hasbro says the other reason it invested in Formlabs was the quality of the parts that come off the build platform. Before Hasbro shipped a single 3D printed part directly to customers, it had to be confident the parts coming off the build platform matched or surpassed the action figures they currently had on the market.

“When we first started seeing the scans come off the Formlabs printer, we knew we had the quality down. We knew we had the skin tones down. We knew we had something there,” says Patrick Marr, Hasbro’s senior director of model development. “And then it was paired with the hair choices. That really made it a complete piece. All of a sudden there, you could start seeing that there’s a bridge between that prototyping stage into the production stage.”

Customers can order custom action figures using the Hasbro Pulse app. Customers download the Hasbro Pulse app, scan their face, select the hair color and pick their preferred action figure.

Related Content

Lithoz, Himed Partner for Research on 3D-Printable Medical-Grade Bioceramics

This collaboration is designed to help grow the range of biocompatible materials suitable for a future that includes highly customized, patient-specific medical solutions that can be printed on demand.

Read MoreEOS Launches Digital Foam Architects Network

EOS created the collaborative additive manufacturing alliance to accelerate time-to-market for 3D printed foam applications.

Read MoreResearchers Develop Method for Creating Customized 3D Printed Metals With Contrasting Properties

Researchers were able to use 3D printing techniques and tweak printing parameters to produce a 3D printed metal with different microstructures that create stronger and weaker regions in the exact locations in the metal that they wanted.

Read MoreAdmatec’s Larger Integrated Binding/Sintering Furnace for Ceramic 3D Printing

Company scales up for more efficient mass customization and serial ceramics 3D printing production lines.

Read MoreRead Next

Video: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More

.png;maxWidth=300;quality=90)