AddUp, SSG to Introduce Tool Steel Optimized for Injection Molding Applications in Additive Manufacturing

SSG developed the Printdur HCT material to meet the requirements of injection molding, enabling manufacturers to significantly reduce production cycles using conformal cooling channels.

AddUp will soon be releasing Printdur HCT, a tool steel optimized for injection molding that meets all customer requirements such as corrosion resistance, hardness and wear resistance for injection molding applications.

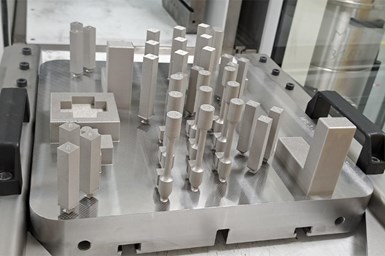

The Printdur HCT was developed by Swiss Steel Group (SSG) based on the conventional standard tool steel 1.2083/AISI420 tailored for additive manufacturing (AM) with focus on powder bed fusion machines like AddUp’s FormUp 350. Following strict internal manufacturing readiness level protocols AddUp’s engineers were able to achieve up to 50% improvement in build speed without cracks and extremely low porosity, ensuring over 99.90% material density when compared to the standard material.

The company also says surfaces can be built up in excellent quality and without any smoke residue. The Printdur HCT material was designed for the requirements of injection molding and can significantly reduce production cycles using conformal cooling channels. Most of the internal cooling channels can be optimally built to a sufficiently good quality, without any support structures.

AddUp says it is committed to developing new materials for the tooling market and was excited to partner with SSG, one of the world’s producers of special steel long products, to collaborate on the development of Printdur HCT.

“Our goal is to use our decades of experience in the atomization and materials technology to design new materials for additive manufacturing,” says Dr. Horst Hill, head of the Special Materials Division at SSG. “The Printdur HCT utilizes the advantages of additive manufacturing to achieve the best material properties. We are very pleased that we have found a strong partner in the tooling sector in AddUp to establish new materials on the market.”

Because of an enhanced hardness range of 53-57 HRC and high wear resistance Printdur HCT offers an improved and longer service life for the mold inserts. With simple one-step heat treatment at 540°C, Printdur HCT achieves ~53HRC hardness and is ready to be used for injection molding applications because the material can withstand high temperatures without losing hardness.

Because the material is produced without nickel and cobalt, significant damage to the environment and the operator could be avoided. SSG, this year's winner of the German Sustainability Award, says it consciously focuses on high sustainability standards with its fully comprehensive powder recycling system. It is also one of the few companies that can already supply almost all products with a significantly reduced CO2 footprint as Green Steel. This has a particularly positive effect on the CO2 impact of its customers in Scope 3.

AddUp’s goal is to revolutionize injection molding applications and improve the efficiency of molds using AM. It expects the development of Printdur HCT and other tooling specific materials in its portfolio to support this mission. “At AddUp, we are committed to taking tooling molds to the next level using the FormUp 350,” says Julien Marcilly, AddUp CEO. “Our company’s history is deeply rooted in tooling applications thanks to our founding partners Michelin and Fives. It is through our experience and expertise in this industry that we continue to push the possibilities of additive manufacturing, proving it a more efficient and productive way to manufacture on an industrial scale.”

Printdur HCT’s manufacturing readiness level 3 has been achieved, which makes it ready for producing high quality proof of concepts. Currently being used on the FormUp 350 machine located at AddUp’s Tooling Competence Centre in Aachen, Germany, Printdur HCT is immediately available for prototyping and once fully developed will be available for end-use production parts.

Related Content

In Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreRekkie AR Ski Goggles Made Possible With 3D Printing: The Cool Parts Show #53

When the electronics enclosure key to these AR goggles proved difficult to mold, 3D printing allowed the inventors to keep the complexity — while also making improvements for assembly and user experience.

Read MoreRead Next

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More

.png;maxWidth=300;quality=90)