AI-Assisted 3D Slicing Software Simplifies Dental 3D Printing Process

The software simplifies the 3D printing process so users don’t need special design training.

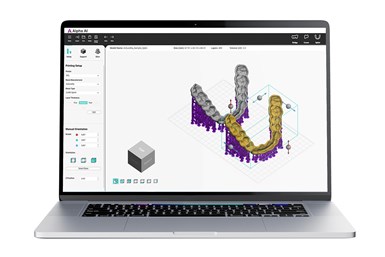

Ackuretta’s Alpha AI slicing software enables optimal AI-generated supports and orientation with just one click. Photo Credit: Ackuretta

Dental 3D printing provider leader Ackuretta offers an AI-assisted 3D slicing software, Alpha AI. This 3D printing slicing software is an evolution of Ackuretta’s Alpha 3D and is said to include several improvements from its predecessor.

The software enables optimal AI-generated supports and orientation with just one click. The AI-assisted slicing software is designed to orient, stack, nest and build supports for 3D prints with the click of a button, providing users with the performance and results they want, in a fraction of the time.

The company says extensive research has driven it toward artificial intelligence as the next logical step in its journey to make 3D dental printing accessible to everyone. Also, the technology is said to provide predictable results every time.

Alpha AI offers a streamlined process to guarantee success and eliminate human error. Users simply import an STL file on the software, click the icon for the desired application and start printing in seconds.

“Up to 75% of 3D printed applications result in failure because of poor orientation. Some clinicians and dental technicians have to go through a learning curve — which leads them to experience failed prints due to a few reasons, such as choosing the wrong printing parameters, not using the correct resin, lack of training and dealing with complex dental 3d printing software,” says Ayush Bagla, Ackuretta CEO. “Alpha AI comes to solve that exact problem. It uses machine learning to analyze data from thousands of real designs and comes up with the optimal orientation for a given application, including adding the necessary supports. Achieve the best result with just one click!”

The software has a universally compatible STL format for CAM software. Alpha AI enables users to orient an application, add the necessary supports and save it not only as i3dp and ibf (Ackureta Solution proprietary file format) but also as an STL file. The company says it aims to empower its customers by offering them a truly open system — for everything from 3D printing solutions to digital dentistry software. Dental experts can configure the print they want on Alpha AI (such as placing it with the right orientation and adding supports) and export the STL file to use on any other 3D printing CAM software specific to non-Ackuretta devices for printing.

Initially, the software will be capable of orienting and creating supports for splints, crowns, bridges and surgical guides. However, the company plans to offer regular updates and improvements every three months to add new features and functions to the dental 3D printing software.

The software is available in two versions — standard and premium. The standard version maintains the original features from ALPHA 3D with an improved UI/UX and includes a 14-day free trial to test the upgrades included in the premium version. After the trial, users can buy a 30-day or 365-day subscription to the premium version.

- Check out our Medical & Dental zone to learn more about some of the latest innovations in dental 3D printing.

Related Content

FDA-Approved Spine Implant Made with PEEK: The Cool Parts Show #63

Curiteva now manufactures these cervical spine implants using an unusual 3D printing method: fused strand deposition. Learn how the process works and why it’s a good pairing with PEEK in this episode of The Cool Parts Show.

Read MoreFormlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read More8 Transformations 3D Printing Is Making Possible

Additive manufacturing changes every space it touches; progress can be tracked by looking for moments of transformation. Here are 8 places where 3D printing is enabling transformative change.

Read MoreRead Next

GE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More

.png;maxWidth=300;quality=90)