Farsoon FS350M-4 Metal AM System Offers Optimal Build Efficiency, Uniform Part Performance

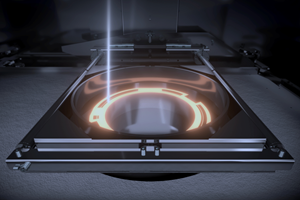

The system is equipped with an advanced multilaser scanning strategy and calibration algorithms which can enable optimal build efficiency and uniformed part performance throughout the build area.

Farsoon’s FS350M-4 is a medium-sized metal 3D production system offering advanced features that enable higher material efficiency and reduced cost. The system is equipped with a build envelope of 433 × 358 × 400 mm and comes standard with a quad 500-W laser configuration.

The FS350M-4 is well suited for medium- to high-volume series production of metal parts for a variety of industries, including molds, tooling, automotive and aerospace. The current material capability of powder materials includes aluminum, titanium, maraging steels and specialized grades of stainless steels.

Equipped with advanced multilaser scanning strategy and calibration algorithms, the systems offers optimal build efficiency, and uniformed part performance throughout the build area. Because of the latest process parameters development — including variable layer thickness, adaptive scanning strategies for infill and detail — the FS350M-4 is able to achieve improved productivity along with excellent part quality. For example, with a shoe mold application, the platform is capable of producing over 95% of all shoe sizes of one pair of shoe molds in a single build, with 60% higher build volume rates compared to other metal LPBF systems in its class.

The metal system includes design features that can reduce the manufacturing cost per part. In large-scale additive manufacturing (AM) production operations, the inert gas consumption is a large portion of the cost. The FS350M-4 limits that expense with its efficient inert gas system as the purge process takes only 11 minutes. During the printing process, the inert gas consumption requires only 3-5 L/min, which the company says is significantly lower than the industry average.

The platform is equipped with an integrated, advanced 3-stage filter module, featuring a back-flush function to ensure longer filter life which helps reduce the cost of the filter changes. In addition, the company says a permanent filter solution will also be available in the near future which will further enhance machine uptime and ease of operations. The closed-loop Powder Management System, intelligent recoating control and advanced layered gas flow design enable higher material efficiency and reduced cost.

The compact system has a machine footprint of 6 m2 with an integrated filtration system. In an AM factory setting, the FS350M-4 enables a high-density layout to achieve maximum throughput per floor area for utilizing a more efficient production layout.

The FS350M-4 also has a high-efficiency top-feed powder system. Once the powder level in the container runs low, the equipped sensor will release a message for refill. The powder refill unit can be easily docked, enabling quick refill of the material without disturbing the build process.

- Read about the Farsoon Flight 403P dual-laser platform which offers high-temperature plastic LPBF. The 403P Series offers a versatile, powerful platform for plastic laser sintering that can achieve two full industrial-scale builds (cylinder size 400 × 400 × 540 mm) within 24 hours.

- Learn about Farsoon’s FS1521M which has 16 lasers for large-format metal additive manufacturing. The FS1521M metal 3D printing platform series offers advanced multilaser scanning strategies with optional modes for efficiency, quality or balanced performance for different manufacturing needs.

Related Content

Drones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read More25 Years Later, What’s Exciting in Electron Beam Powder Bed Fusion?

Often seen as runner-up to laser powder bed fusion, are we finally in the golden age of the electron beam?

Read MoreVariable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read More

.png;maxWidth=300;quality=90)