Horizon Microtechnologies’ Functional Coatings for Conductive, Durable Parts

Formnext 2023: Horizon Microtechnologies offers functional coatings on 3D printed parts with micrometer-scale precision, enabling the micro-additive manufacturing of conductive and durable parts.

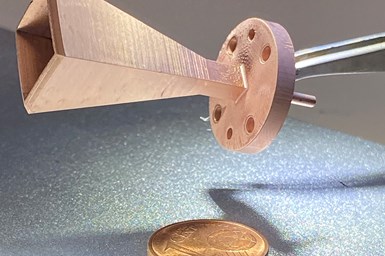

Horizon Microtechnologies has developed a template-based 3D microfabrication technology that gives manufacturers the ability to add conductivity to all or selected parts of a 3D-microfabricated template. Photo Credit: Horizon Microtechnologies

Horizon Microtechnologies’ coating processes for microstructures enhance the functionality of microstructures, predominantly for parts produced via micro-additive manufacturing (AM). By adding nonmetallic conductive, environmentally-resistant and metallic coatings to polymer micro-AM parts and components, Horizon’s coatings open up the advantages of AM to sectors and applications that were previously unable to utilize AM due to a limited palette of materials that micro AM was able to process, which in turn restricted part functionality.

This technology is well suited for previously unserved areas of industry by adding material and functionality to the microstructure, typically with a coating process. “Our company has a unique understanding of the micro-AM based 3D microfabrication process chain. And, while we provide a suite of post-build coating processes, our ability to now build parts in-house on the BMF machine allows us to provide a complete technology infrastructure in-house,” says Andreas Frölich, Horizon CEO. “This means customers can benefit from a truly vertically integrated solution from design to delivery. It also speeds up the development of our post-build coating technologies which will have a profound impact on industry by continually broadening the use of micro-AM into different application areas.”

Horizon says the its vision is to stimulate the use of micro-AM into application areas that were previously unable to take advantage of the technology’s inherent agility and manufacturing efficiency due to material constraints. The company recently purchased BMF’s microArch S240 micro AM machine. The company says it chose to work with Boston Micro Fabrication (BMF) because its micro-AM platforms are suitable for both prototypes and end products, and push the boundaries of resolution, accuracy and precision in AM technology and promote miniaturization with new applications in many industries.

The microArch machines use the process of projection microstereolithography (PµSL), which combines the advantages of digital light processing (DLP) and stereolithography — a flash of light triggers the rapid photopolymerization of an entire layer of resin. Continuous exposures increases the build speed, and components are built up from the top down in a resin basin, which reduces the need for support structures, all of which helps to streamline the micro-AM workflow for Horizon.

Frölich says Horizon offers coating processes that offer versatility, enabling the production of intricate parts using the microArch S240. “Horizon can act as an end-to-end product development and contract manufacturing partner, influencing the design of micro AM parts to optimize them for end-use functionality and also optimize them for the application of our proprietary coating technologies,” Frölich adds. “We can wholly or selectively coat micro-AM parts with a nonmetallic conductive layer, add environmental resistance to parts, enabling the creation of microscale devices that are more durable, reliable and better suited for use in harsh environments — such as in the presence of aggressive chemicals and/or high temperatures, and can wholly or selectively coat micro-AM parts with copper.”

Horizon’s metallic copper coatings are typically in the 1-2 micron thickness range, which is sufficient for many applications. Also, the company’s process can also coat internal channels and undercuts to some degree, with the channel’s aspect ratio being the limiting factor rather than the absolute length. This is a significant advance for copper coating of micro-AM templates, the company says.

- Learn more about Horizon Microtechnologies’ micro additive manufacturing for conductive, environmentally-resistant parts. The company has developed a template-based 3D microfabrication technology that gives manufacturers the ability to add conductivity to all or selected parts of a 3D-microfabricated template.

Related Content

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreRead Next

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More